Q & A

If you have any product issues, please contact us! We will provide you with the right solution for you!

Contact UsYQZF4 - ※ - 15

Key:

Coaxial valve, pneumatic booster pump

Product Description

Effectively solve the residual pressure and ticking water in the spindle hole when changing tools and changing parts

| Product introduction

— Compact structure

— Reduce leakage points

— Control signal sharing

— Quickly establish high voltage

— System safety protection

— Improve machine efficiency

Advantage

1: Use high-pressure four-way valve to synchronously solve the problems of frequent start and stop, overpressure unloading, and multi-pressure switching of high-pressure pumps, and improve the service life and processing quality of pumps;

2. Solve the problem of long establishment time of internal cooling pressure and affect the processing cycle; Each tool change can save 2-3 seconds or more;

3. Effectively solve the problem of residual pressure in the spindle hole and ticking water caused by the contamination of the positioning surface and the water immersion of electronic components on the manipulator during tool change and replacement, and avoid safety problems such as tool change with pressure;

4. Improve the work efficiency, processing quality and safety of the machine tool.

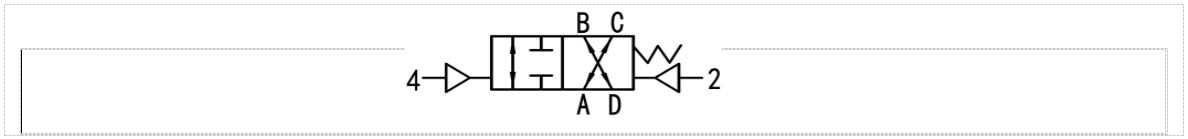

| Feature symbols

| Technical parameters

|

Basic Specifications |

function |

Two digits and four links |

|

connect |

3/8 , 1/2 , 3/4 |

|

|

Interface form |

G,Rc,NPT |

|

|

Pressure range |

0-12MPa |

|

|

function |

Double air control, spring normally closed |

|

|

Body material |

Stainless steel, high performance alloy steel, aviation aluminum |

|

|

Seat sealing material |

Synthetic resin-to-metal, metal-to-metal, aluminum alloy |

|

|

Sealing material |

HPU,NBR,EPDM,PTFE,FKM,FFKM |

|

|

vacuum |

<10-7Pa.L/s |

|

|

medium |

Gaseous, liquid, gel-like, granular, highly polluting, corrosive |

|

|

Flow |

A→ B, A→C, B→D (or see drawing annotation) |

|

|

Operation time |

50-3000ms (maximum response time 20ms) |

|

|

Ambient temperature |

-10~50℃ |

|

|

Media temperature |

-10~60°C (conventional), -40~260°C |

|

|

authentication |

CE, ISO9001, vacuum certified |

|

|

Electrical specifications |

Rated voltage & power |

24VDC & 2.5W, 220VAC & 2.5VA, special voltages on request |

|

Protection & heat resistance rating |

IP65 & Level B |

|

|

connect |

DIN type C plug (PG7) as standard, M12X1 socket, special connection on request |

|

|

Manual control mode |

Pilot operated solenoid manual pushbutton |

|

|

Air-driven regulations |

Control mode |

Air controlled, two-position 5-way pilot solenoid valve |

|

temperature |

-10~50°C(no condensation) |

|

|

Drive pressure |

2-8 bar |

|

|

lubrication |

No lubrication required |

| Product application

Process control, petrochemical, environmental technology, machine tools and other equipment

Related Products

Product Inquiry

About Us

Industry Applications

Technical Service

News

Contact

Service Hotline: ( 86 ) 411-88705800 Add: Building 1, No. 10-5 ShuangD-Port Fifth Street, Dalian Economic and Technological Development Zone

Copyright © 2022 Dalian Really Fluid Technology Co., Ltd Powered by www.300.cn Seo Business License